Injection molding is a powerful manufacturing process that allows for the mass production of complex plastic parts with high precision. However, for startups, entering this space comes with a unique set of challenges that can make the journey seem daunting. From high upfront costs1 to technical complexities2 and limited access to manufacturers, startups must navigate a maze of obstacles to bring their products to market. But with the right strategies and knowledge, these hurdles can be overcome.

Startups face significant challenges in injection molding, including high costs, technical complexities, limited access to manufacturers, and knowledge gaps, but strategic planning and cost-effective solutions can help mitigate these issues.

Understanding these challenges in depth is crucial for startups looking to leverage injection molding3 for their products. Below, we explore each obstacle in detail, offering insights and practical solutions to help you make informed decisions.

Injection molding is cost-prohibitive for startups due to high tooling expenses.True

Mold creation, especially for durable steel molds, can cost tens of thousands of dollars, which is a significant barrier for startups with limited funding.

Startups can easily find manufacturers willing to take on small production runs.False

Many manufacturers prioritize large orders, making it difficult for startups to find partners for smaller, low-volume production runs.

Table of contents Hide

- What are the Financial Challenges in Injection Molding for Startups?

- What are the Technical Challenges in Injection Molding for Startups?

- How Do Startups Overcome Limited Access to Manufacturers?

- What Knowledge Gaps Do Startups Face in Injection Molding?

- How Can Startups Mitigate These Challenges?

- Conclusion What are the Financial Challenges in Injection Molding for Startups? Financial hurdles are often the most daunting for startups venturing into injection molding. The process requires significant upfront investment, particularly in tooling and production minimums.

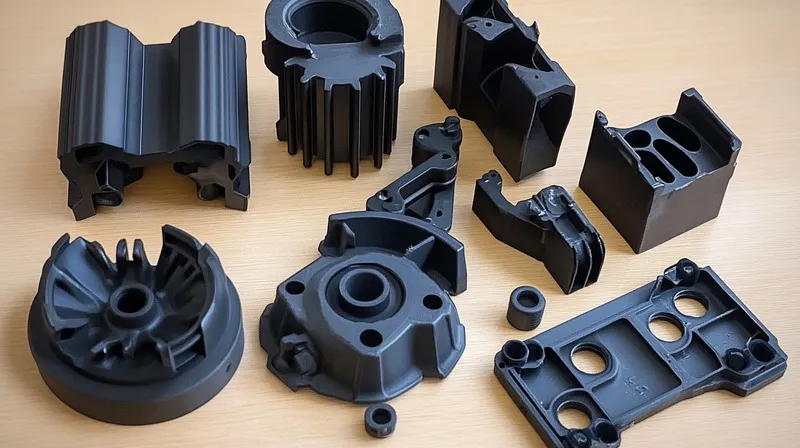

A collection of black 3D printed engineering parts arranged on a wooden surface injection molding products Startups face high tooling costs and production minimums in injection molding, which can strain limited budgets and delay product launches.

Challenge Description Impact on Startups Tooling Costs4 Molds, especially steel ones, can cost between $10,000 and $100,000 depending on complexity and material. High upfront costs can deplete startup capital. Production Minimums5 Manufacturers often require large orders (e.g., 10,000+ units) to justify setup costs. Startups may struggle to meet these minimums, leading to higher per-unit costs. Funding Requirements6 External investment or loans are often needed to cover initial costs. Securing funding can be time-consuming and risky. Tooling Costs Creating molds is one of the most expensive aspects of injection molding. Steel molds, which are durable and ideal for high-volume production, can cost tens of thousands of dollars. For startups, this can be a significant barrier, especially when budgets are tight. Aluminum molds offer a cheaper alternative but are less durable and may not be suitable for long-term production.

Production Minimums Many manufacturers require large minimum order quantities (MOQs) to make the production run economically viable. For startups, meeting these MOQs can be challenging, as they may not have the demand or capital to support large initial orders. This can lead to higher per-unit costs or delays in production.

A variety of colorful 3D printed gears arranged on a flat surface injection molding products Funding Needs To cover the high costs of tooling and production, startups often need to seek external funding, such as venture capital or loans. However, securing this funding can be difficult, especially for early-stage companies without a proven track record.

Aluminum molds are a cost-effective alternative for startups.True

Aluminum molds are cheaper than steel and suitable for low to medium production runs, making them ideal for startups testing the market.

Startups can avoid high tooling costs by using 3D printing for production.False

While 3D printing is useful for prototyping, it is not a cost-effective or scalable solution for mass production compared to injection molding.

What are the Technical Challenges in Injection Molding for Startups? Injection molding is a highly technical process that requires precise control over various parameters to produce high-quality parts. For startups without prior experience, mastering this complexity can be overwhelming.

Startups face technical challenges in injection molding, including process control7, material selection8, and defect prevention9, which require expertise and careful planning.

A black 3D printed engine component with multiple circular openings and detailed structure injection molding products Process Control The injection molding process involves managing critical variables such as temperature, pressure, and cooling time. Even small deviations can lead to defects like warping, sink marks, or incomplete filling. For startups, ensuring consistent quality across production runs can be difficult without experienced staff or advanced equipment.

Material Selection Choosing the right material is crucial for the success of the final product. Different plastics have varying properties, such as flexibility, heat resistance, and cost. Startups must balance these factors while considering the impact on production costs and part performance.

Blue, green, and yellow plastic pellets with test tubes injection molding products Defect Prevention Common defects in injection molding include flash (excess material), short shots (incomplete filling), and weld lines (visible seams). Preventing these issues requires precise tuning of the process parameters and mold design, which can be challenging for newcomers.

Material selection is critical for ensuring product quality in injection molding.True

The choice of material affects the part's durability, flexibility, and cost, making it a key decision in the production process.

Injection molding is a simple process that requires minimal technical knowledge.False

Injection molding is highly technical, requiring precise control over temperature, pressure, and other variables to avoid defects.

How Do Startups Overcome Limited Access to Manufacturers? Finding a manufacturing partner willing to work with small orders is a common struggle for startups. Many injection molding companies prioritize large, established clients, leaving startups with limited options.

Startups often struggle to find manufacturers willing to take on small production runs, which can delay product launches and increase costs.

Several black flashlight components arranged on a white background, including a tubular body, a lens ring, and various other parts injection molding products Manufacturer Priorities Injection molding manufacturers typically prefer high-volume orders because they are more profitable. Startups, with their smaller initial production needs, may find it difficult to secure a partner willing to take on low-volume runs. This can lead to longer lead times and higher costs.

Strategies for Finding Partners To overcome this challenge, startups can:

Look for manufacturers that specialize in low to medium-volume production. Use online platforms like ThomasNet or MFG to find suppliers open to smaller orders. Consider working with local manufacturers who may be more flexible with order sizes. Startups can easily find manufacturers for small production runs.False

Many manufacturers prioritize large orders, making it challenging for startups to find partners for smaller runs.

Online platforms can help startups connect with manufacturers open to low-volume production.True

Platforms like ThomasNet and MFG allow startups to search for manufacturers based on specific criteria, including order size.

What Knowledge Gaps Do Startups Face in Injection Molding? Navigating the injection molding industry requires a deep understanding of materials, processes, and market dynamics. For startups, bridging these knowledge gaps often requires external expertise, which can be costly.

Startups face knowledge gaps in injection molding10, including understanding materials, processes, and industry standards, often necessitating external expertise.

Various sizes= injection molding products Industry Know-How Understanding the nuances of injection molding, such as mold design, material compatibility, and quality control, is essential for success. Startups may lack this expertise in-house, requiring them to hire consultants or invest in training.

Regulatory Compliance For industries like medical devices or automotive, strict regulatory standards must be met. Startups must ensure their products comply with these regulations, which can be complex and time-consuming.

A collection of different syringes with varying sizes= injection molding products Cost of Expertise Hiring consultants or experienced engineers to bridge knowledge gaps can be expensive, adding to the financial burden on startups.

Startups can succeed in injection molding without external expertise.False

The technical and regulatory complexities of injection molding often require startups to seek external expertise to ensure success.

Regulatory compliance is a minor concern for startups in injection molding.False

In regulated industries like medical devices, compliance is critical and can be a significant challenge for startups.

How Can Startups Mitigate These Challenges? While the challenges are significant, startups can take strategic steps to mitigate them and increase their chances of success in injection molding.

Startups can mitigate injection molding challenges by using cost-effective molds, leveraging prototyping, and partnering with flexible manufacturers.

A black metal engine part with circular and geometric cutouts, photographed on a light background injection molding products Cost-Effective Molds Startups can opt for aluminum molds instead of steel for early production runs. While less durable, aluminum molds are significantly cheaper and can be used for low to medium-volume production.

Prototyping with 3D Printing Before committing to expensive molds, startups can use 3D printing to create prototypes and test designs. This reduces the risk of costly design errors and allows for faster iteration.

Partnering with Flexible Manufacturers Startups should seek out manufacturers that specialize in small to medium-sized orders. Building relationships with these partners can lead to more favorable terms and better support.

A clear plastic container with a rectangular shape and recycle symbol on its side injection molding products Investing in Knowledge While hiring external expertise can be costly, it is often a necessary investment. Startups can also leverage online resources, industry forums, and training programs to build in-house knowledge.

3D printing can be used for mass production in place of injection molding.False

3D printing is ideal for prototyping but is not cost-effective or scalable for mass production compared to injection molding.

Aluminum molds are a viable option for startups looking to reduce tooling costs.True

Aluminum molds are cheaper and suitable for low to medium-volume production, making them a good choice for startups.

Conclusion Injection molding offers startups the ability to produce high-quality, complex parts at scale, but it comes with significant challenges. High costs, technical complexities, limited access to manufacturers, and knowledge gaps can make the process seem overwhelming. However, by understanding these obstacles and implementing strategic solutions—such as using cost-effective molds, leveraging prototyping, and seeking flexible manufacturing partners—startups can successfully navigate the injection molding landscape.

For startups willing to invest the time and resources, injection molding can be a game-changer, enabling them to bring innovative products to market efficiently and cost-effectively.